The Project

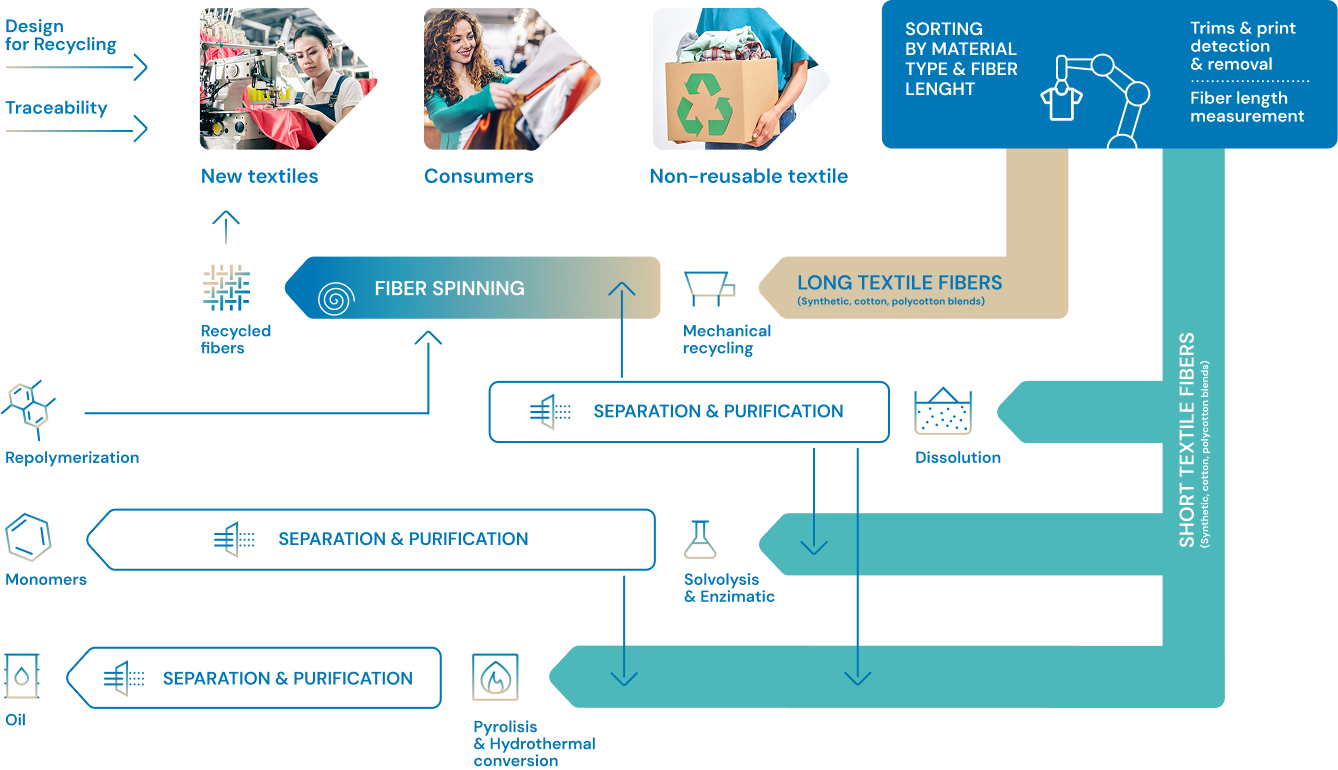

STREP delivers a holistic solution that spans the full textile recycling value chain, integrating automated disassembly, design for recycling, and smart chemical processes. It’s designed to create circular, high-performance materials from non-mechanically recyclable textile waste.

STREP’s Vision

and Approach

STREPs mission is to allocate the right textile fibres to the right recycling flows, maximizing the value and minimizing the environmental footprint of every fibre.

This will be achieved through:

Advanced Sorting

Incorporates fibre length measurement, cost-efficient sensors, automated trim removal, and AI-driven self-learning

Smart Design

Develops guidelines for easier disassembly of complex, multi-layered textiles.

Mechanical Recycling Integration

Utilises sorted long fibres for producing high-quality recycled materials.

Targeted Chemical Recycling

Tailors processes to specific fibre types and lengths to enable closed-loop yarn production.

Objectives

Automate textile sorting and accessory removal

Maximize fibre recovery using chemical and enzymatic methods

Digitally track textile components from input to output

Provide scalable models for industrial circularity

STREP Actions Timeline

1

Requirements definition and tech scouting

2

Prototype and test integrated systems

3

Pilot demonstration at industrial sites

4

Data analysis, optimization, and scalability planning

Two of STREP’s breakthrough innovations focus on improving

textile sustainability before products even reach consumers:

Recyclability-by-Design

Guidelines

Development of a comprehensive design matrix to guide product designers in creating textiles that are easier to disassemble and recycle. This includes recycling-friendly construction techniques that minimize complex trims and incompatible materials.

Traceability and Circular Product Identity

Introduction of digital enablers such as RFID-based circular identification, digital product passports, and marketplace integration. These tools enable sorting of textiles into the right recycling streams, enhance transparency, and allow operational data collection for continuous improvement and customer engagement.

After textile waste is collected, STREP introduces several

advanced technological solutions:

The ultimate goal is to produce 100% closed-loop recycled yarns

exclusively from post-consumer textiles—striking a balance between

sustainability, cost-efficiency, and quality:

Sorting efficiency boost

Post-consumer recycled yarn

Accessory removal efficiency